FOOD INDUSTRY

CONSTRUCTION/MINING

OFFSHORE/ENERGY

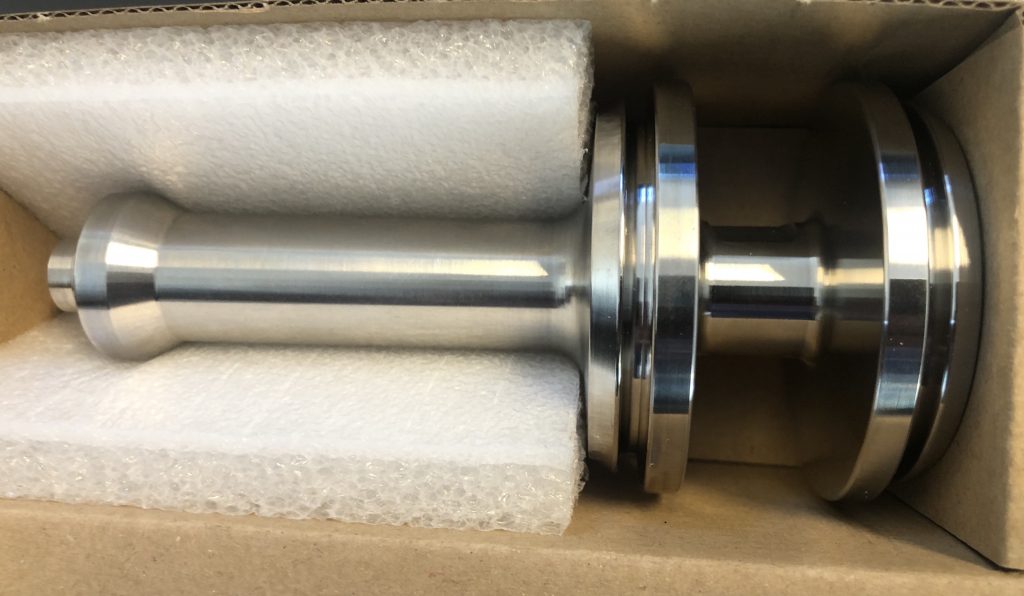

8 cnc lathes from 6mm up to 570mm diameter swing. Distance between centers 2000 mm., with spindle bores up to 156 mm.

TURNING

MILLING

WELDING

Our machine park is versatile and growing with new machines that are very energy friendly in line with the company’s ISO 14001 environmental policy. In addition to the machine park, we have our own forging department for tasks related to machining. We have an extensive raw material stock of steel 304, 316, duplex m.m.

HEAVY DUTY MACHINES

spindLE BORE UP TO 156 mm

Our latest 2020 investment in German WEILER machines, all powerful machines with cycle-controlled and simultaneous programs, are unique for demanding processing of long workpiece tubes, shafts, large bushings, locking rings and extruders.

The machines are used successfully for products for the food machine and decanter industry where we ensure surfaces all the way down to Ra 0.2 in addition to Ra 0.8 and Ra 3.2 standards.

2020: 2 X weiler e50 heavy duty cyCLE CONTROLLED MACHINES

- Centre hight 280 mm

- Swing over bed 570 mm

- Swing over cross slide 340 mm

- Distance between centre 2.000 mm

(via spindle 4.000 mm) - Spindle nose DIN 55027 (DIN ISO 702-3)

- Spindle bore 128 mm + 83 mm

- Spindle diameter in front 120 mm

- Simulation programming

2020: weiler E40 cyCLE ControlleD Machine

- Centre hight 210 mm

- Swing over bed 435 mm

- Swing over cross slide 200 mm

- Distance between centre 1.000 mm

- Spindle nose DIN 55027 (DIN ISO 702-3)

- Spindle bore 66 mm

- Spindl diameter in front 110 mm

- Simulation programmering

Energy efficiency

- a SOLvang priority

WEILER cycle-controlled lathes implement energy-saving potential through integrated e-TIM software.

Timer-controlled emergency stop operation from standby mode according to operator requirements.

Intelligent drive control with energy recovery: Dynamic energy control controls the flow of energy into the machine. Instead of meaninglessly converting excess braking energy into heat, it is fed back into the supply network.

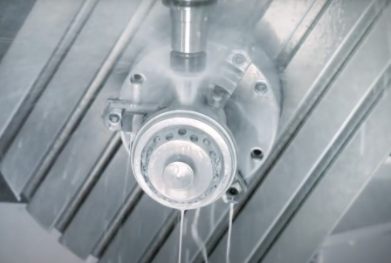

We CNC mill in various types of materials, in series sizes from single-piece work and up to medium-sized series.

Material types for production are S235, S355, C45, AISI 303, AISI 304, AISI 316, duplex, bronze, aluminum and plastic materials.

5 axis high speed

Simultaneous programming for 5-axis toolpaths

2019 Haas ucm 750 5 axis high speed machining

- Simultaneous programming for 5-axis toolpaths

- 12,000 rpm

- Side-mounted tool changer 40 + 1, BT 40

- Automatic tool and workpiece measurement

- Automatic calibration, synchronous cutting

- Mastercam drawing programs

Youngtech YCM 1568 CNC Machining Centre Box

- X-axis 1568 cm

- Y-axis 720 mm

- Z-axis 670 mm

- Bed size 1700×600 mm

- 10.000 RPM

- Loading capacity 1,000 kg

Emcomill cnc e600

- High-performance milling spindles. flexible tool system, programming software for productions.

- Control technology from Siemens and Fanuc

shibaura bt-8cr

- Horizontally large drilling rig